Ever wonder how something so full of holes can be so incredibly strong? It’s one of those beautiful paradoxes of the industrial world. You see it everywhere—under your feet as a grippy walkway on an oil rig, shading a stunning modern building facade, or even protecting a heavy-duty fan. It’s the unassuming yet utterly indispensable expanded metal sheet. But its journey from a boring, solid coil of metal to a versatile, diamond-patterned powerhouse is a story of clever engineering and brute force. The magic isn’t in adding material, but in transforming it. Imagine taking a sheet of metal and, instead of cutting pieces away and welding them together, you just… stretch it. That’s the core of it. A single, continuous piece of steel, aluminum, or stainless steel is slit and pulled apart, creating a web of strands and openings in one seamless action. This process, deceptively simple in concept but precise in execution, gives birth to a material with a unique set of properties that welded wire or perforated metal just can’t match. It’s a testament to the idea that strength often lies in structure, not just in mass.

The Stretching Ritual: Birth of the Sheet

Let’s dive into how this transformation happens. Forget any notions of weaving wires together; the creation of an expanded metal sheet is a monolithic event. It starts with a massive coil of metal—its composition (like the stainless steel specialties from a place like HP Stainless Steel Mesh, for instance) chosen for the job ahead. This blank, solid sheet is fed into a machine called an expander. Here’s where the first critical step occurs: a blade, often with a knife-like edge, descends and makes a series of staggered, parallel slits in the metal. It’s crucial to understand these aren’t full cuts; they’re precise, controlled incisions. The sheet now looks a bit like a musical staff waiting for notes. Then comes the dramatic part. The edges of this slit metal are gripped by powerful jaws or hooks. With immense hydraulic force, these jaws pull the sheet apart, stretching it in a direction perpendicular to the slits. This is the “expansion” in expanded metal sheet.

As the metal stretches, those slits yawn open, morphing into the characteristic diamond-shaped openings. The solid metal between the slits is drawn out, becoming the strong, ligament-like strands of the final product. Because the material is stretched, not cut away, the strands have a slight three-dimensionality; they’re not flat but have a gentle, inherent rigidity. This entire process happens in one continuous, flowing motion. The beauty is in its efficiency. There’s almost no waste material, or “skeleton,” left over. The original metal is simply redistributed, becoming larger in area, lighter in weight, but maintaining a remarkable continuity of grain structure. This lack of waste is a huge win economically and environmentally. You’re getting more coverage and functionality from the same starting weight of metal. The operator can control the final product by adjusting the depth of the slits, the pattern of the blade, and the amount of stretch. Want a small, tight pattern for filtering? Less stretch. Need a wide-open pattern for a security screen? More stretch. This flexibility at birth is what sets the stage for the expanded metal sheet’s countless applications.

A Tapestry of Traits: What Makes It Special

So, what does this stretching ritual actually gift to the expanded metal sheet? Its properties are a direct, elegant result of the manufacturing process, creating a combination of features that are hard to find in any other single material.

First and foremost is its structural integrity and one-piece strength. Since it’s made from a single piece of metal with no welded or fastened joints, stress is distributed evenly across the entire sheet. There’s no weak point where components are joined. The strands flow into each other seamlessly, making it incredibly resistant to unravelling or coming apart, even if a strand is cut or damaged at the edge. This makes an expanded metal sheet fantastically durable for high-impact or high-load applications like industrial flooring and platforms.

Then there’s the safety and slip resistance. Those raised strands and open diamonds aren’t just for looks. They provide an exceptional grip underfoot, whether the surface is wet, oily, or dusty. Liquid, debris, and even snow simply pass through the openings, eliminating puddles and slick spots. This inherent safety feature is why you’ll find it on stair treads, catwalks, and truck ramps wherever worker safety is paramount. It’s a grip built into its very DNA.

Next, we have free flow and permeability. This is the yin to its strength’s yang. The expanded metal sheet is a master of allowing things to pass through while still providing a robust barrier. Air, light, sound, water, and heat can all move through its openings. This makes it perfect for applications that need ventilation, filtration, screening, or visibility alongside security or protection. Machine guards use it to contain equipment while allowing airflow for cooling and visibility for operators. Filters use specific grades of expanded metal sheet to sort materials by size.

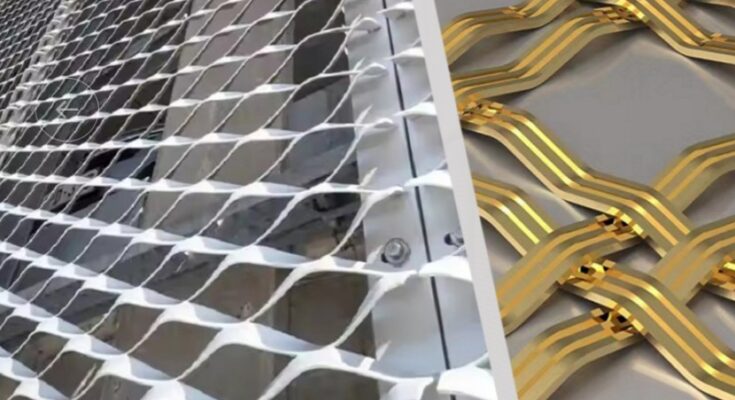

Finally, its versatility and aesthetic potential are boundless. It can be made from almost any malleable metal: carbon steel, stainless steel, aluminum, even exotic alloys like titanium or copper. Each base material brings its own properties—corrosion resistance, conductivity, weight savings. Furthermore, it can be finished in countless ways: left with a raw mill finish, hot-dip galvanized for outdoor use, powder-coated in any color imaginable, or even anodized. This is where the expanded metal sheet transcends its industrial roots. Architects love it for the dynamic play of light and shadow it creates on a building’s exterior, crafting facades that change with the time of day.

From Grit to Glamour: Where It Gets Used

The applications of expanded metal sheet are a direct map of its properties in action. You can literally follow its journey from the grittiest industrial settings to the most polished design studios.

In the heavy-duty industrial realm, it’s the undisputed champion of flooring and walkways. Its combination of strength, slip resistance, and permeability is unbeatable for factories, power plants, offshore platforms, and wastewater treatment facilities. It’s also the go-to material for machine guards, safety fences, and partitions in plants. In filtration and screening, different mesh sizes of expanded metal sheet are used to classify everything from mined rocks and sand to food products and pharmaceuticals. Its durability allows it to withstand the punishing abrasion of tons of material sliding across it.

In architecture and construction, it has been embraced as a multifaceted building material. As sunshades and facade cladding, it controls solar heat gain while creating stunning visual effects and maintaining outward views. As interior design elements, it becomes feature walls, ceiling panels, balustrades, and elevator cladding, adding texture and an industrial-modern vibe. Security is another big sector, where robust expanded metal sheet is used for window guards, prison fencing, and enclosure panels, providing a formidable barrier without the closed-in feeling of a solid wall.

But it gets even more interesting in specialized and unexpected applications. That same conductive, high-surface-area structure that makes a great filter also makes it an excellent component in some battery and fuel cell designs, acting as a current collector. You’ll find it in automotive grilles, speaker covers (for its acoustic transparency), agricultural equipment, and even in art installations and sculptures, where artists are drawn to its texture and geometric patterning. The expanded metal sheet is, in many ways, a blank canvas. Its form is defined by its function, but its potential is limited only by imagination. Whether it’s providing a safe path over a dangerous pit or creating a mesmerizing pattern of light on a museum wall, it does so with the same fundamental, stretched-from-solid integrity. It’s a reminder that true versatility comes not from complexity, but from a simple, brilliant idea executed perfectly—the idea that stretching metal can create something far more useful than the solid original.