Industrial expectations continue shifting as operations seek smoother methods. Teams search for dependable structures that keep projects aligned. Increased demand often grows because machining vietnam supports smoother industrial planning. Steady coordination becomes easier when each production stage follows consistent transitions.

Enhanced Workflow Structures Advancing Output

Modern workflows depend heavily on refined sequencing that supports steady progress. Operators value smoother transitions because they encourage predictable momentum. Each stage responds better when supported by clear structural alignment.

- Coordinated steps keep overall timing steady

- Organized routing ensures balanced movement flow

- Adaptable layouts simplify ongoing production shifts

- Structured planning enhances steady task progression

Stronger workflow clarity emerges once each action supports the next. Production stability rises naturally as teams guide processes with intention. Reliable pacing becomes easier when every transition remains consistent.

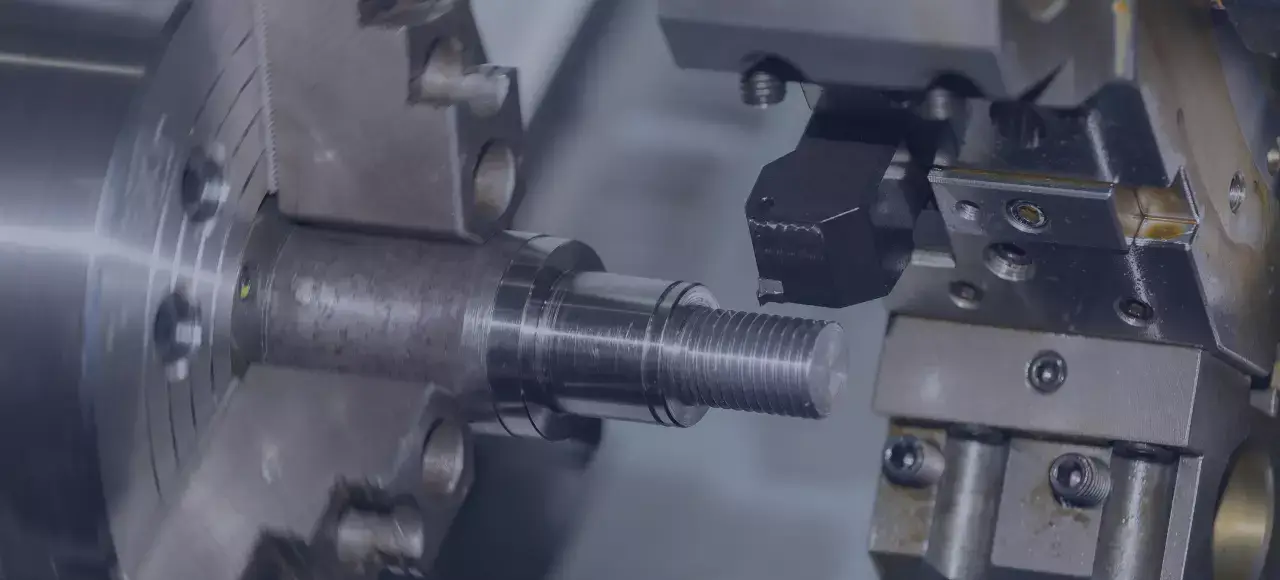

Refined Component Accuracy Supporting Efficiency

Accurate components influence broader efficiency across multiple operations. Consistent shaping improves finishing time by reducing corrective tasks. Teams benefit from reliable measurements that add confidence throughout development.

- Tight tolerances stabilize ongoing machining performance

- Uniform shaping improves finishing stages significantly

- Balanced dimensions increase dependable fitting outcomes

- Reliable accuracy reduces repeated fabrication efforts

Precision encourages cleaner output that aligns well with detailed expectations. Focused adjustments contribute measurable improvements to quick turnaround. Smooth compatibility across parts strengthens predictable production outcomes.

How does precision improve outcomes?

Precision helps operators reduce unnecessary revisions over extended work cycles. Teams notice smoother flow because careful shaping supports predictable alignment. Smaller adjustments feel easier when each detail responds consistently. It keeps projects progressing with fewer unexpected delays.

What boosts machining reliability most?

Reliability improves whenever equipment follows consistent calibration habits throughout its usage. Operators trust results more when measurements stay stable during changing workloads. Processes remain steady because dependable tools maintain structural balance. Reliable flow encourages smoother decision making across complex tasks.

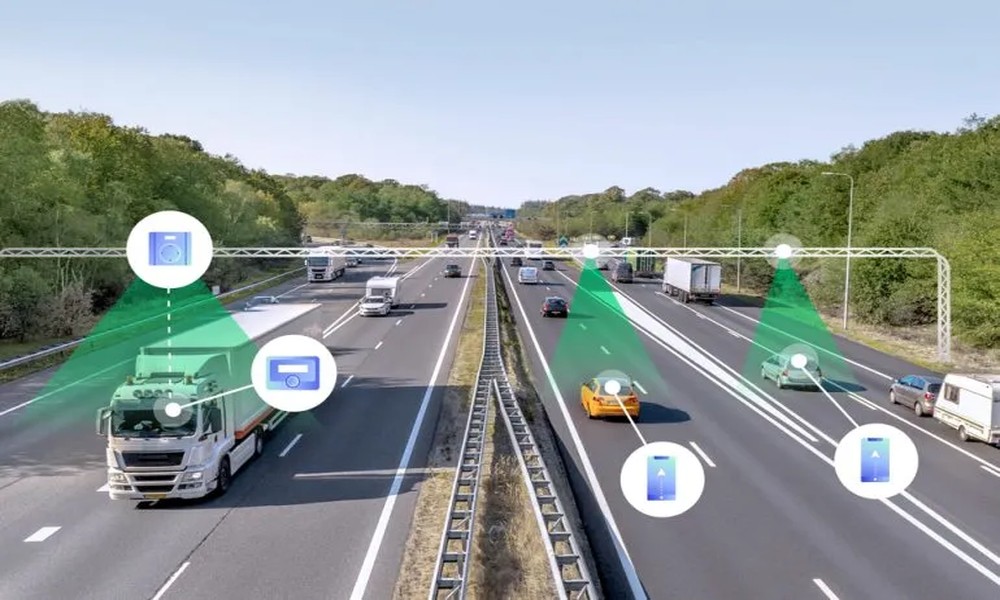

Integrated Technology Elements Supporting Consistency

Growing industrial needs often require systems capable of steady adaptation. Coordinated tools help streamline transitions during shifting production phases. Ongoing adjustments feel more coordinated since machining vietnam reinforces stable production insight.

- Updated controls maintain smoother operating responses

- Integrated systems strengthen predictable machining cycles

- Coordinated features help reduce unnecessary slowdowns

- Automated checks support balanced processing efforts

Improved functionality makes each step easier to manage across evolving demands. Consistent tracking helps teams respond quickly to subtle changes. Refined coordination supports dependable progress across extended production windows.

Why choose advanced setups?

Advanced setups help teams reach expected accuracy with less difficulty. Operators appreciate supportive calibration that keeps overall structure aligned. It becomes easier to handle demanding shapes through smarter adjustments. The experience improves because processes respond more predictably.

Steady Direction Toward Improved Performance

Industrial output grows when structured systems guide every transition clearly. Coordinated responses make complicated tasks easier across extended stages. Teams gain confidence as operations maintain predictable and stable momentum. Each aligned action moves production toward a more efficient direction.

Comments